Eliminating Defects: The Case Against Lubricating Wax in Aluminium Manufacturing

When working with aluminium or non-ferrous materials in metal manufacturing, lubricating or cutting wax is commonly suggested as a solution to prevent the clogging of grinding pads or binding of cutting discs.

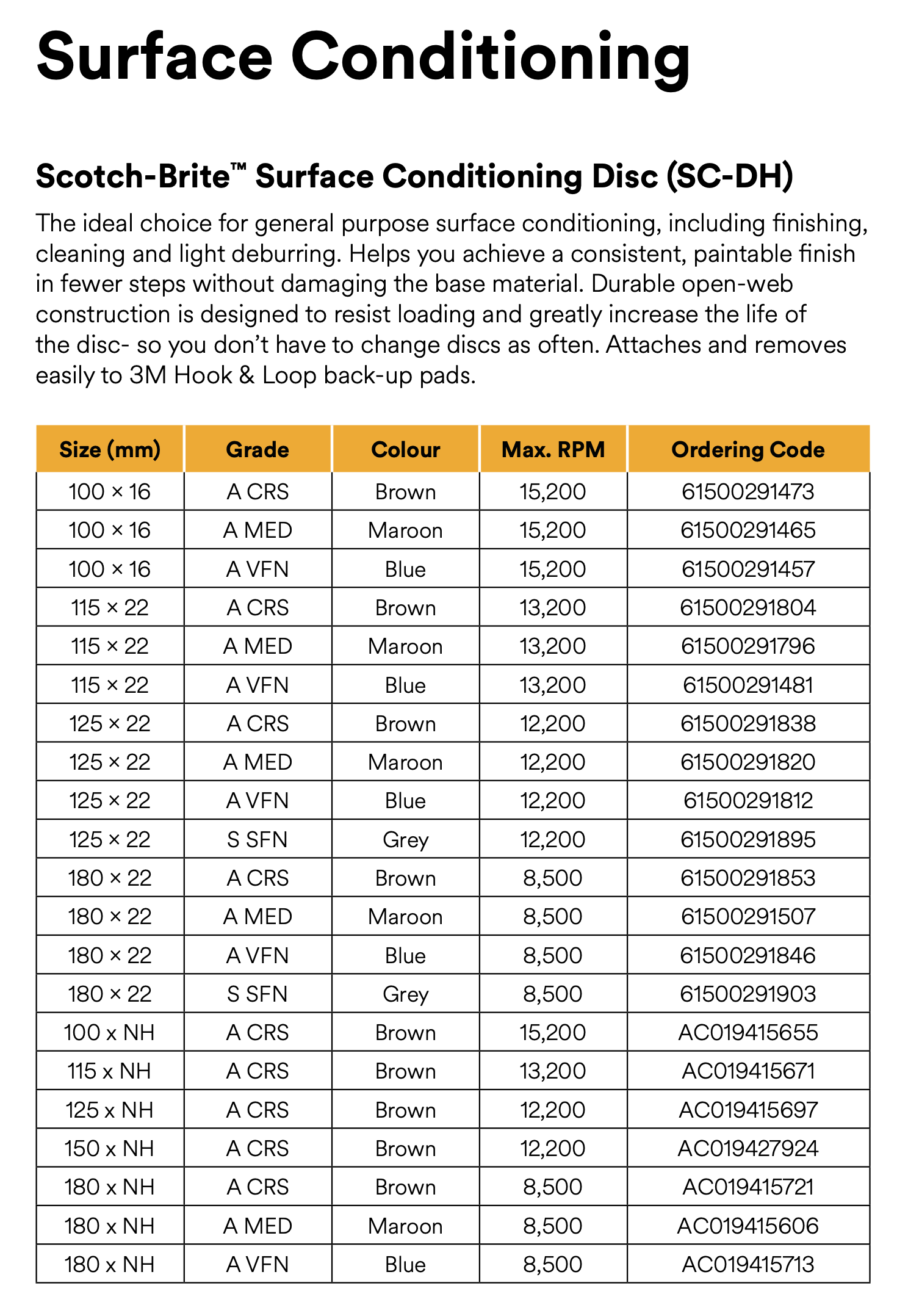

Whilst such products can be effective for the fabricator, the wax effectively soils the substrate with a difficult to remove contaminant that can negatively impact downstream painting or powder coating processes resulting in unnecessary defects. Wax residues are often spread randomly across the product surfaces due to splattering off the grinding discs and/or through interaction with buildup of wax on work tables and manual handling. Many of these lubricating wax products are generally not water-soluable and therefore are not effectively or completely removed during many chemcial pre-treatment processes.

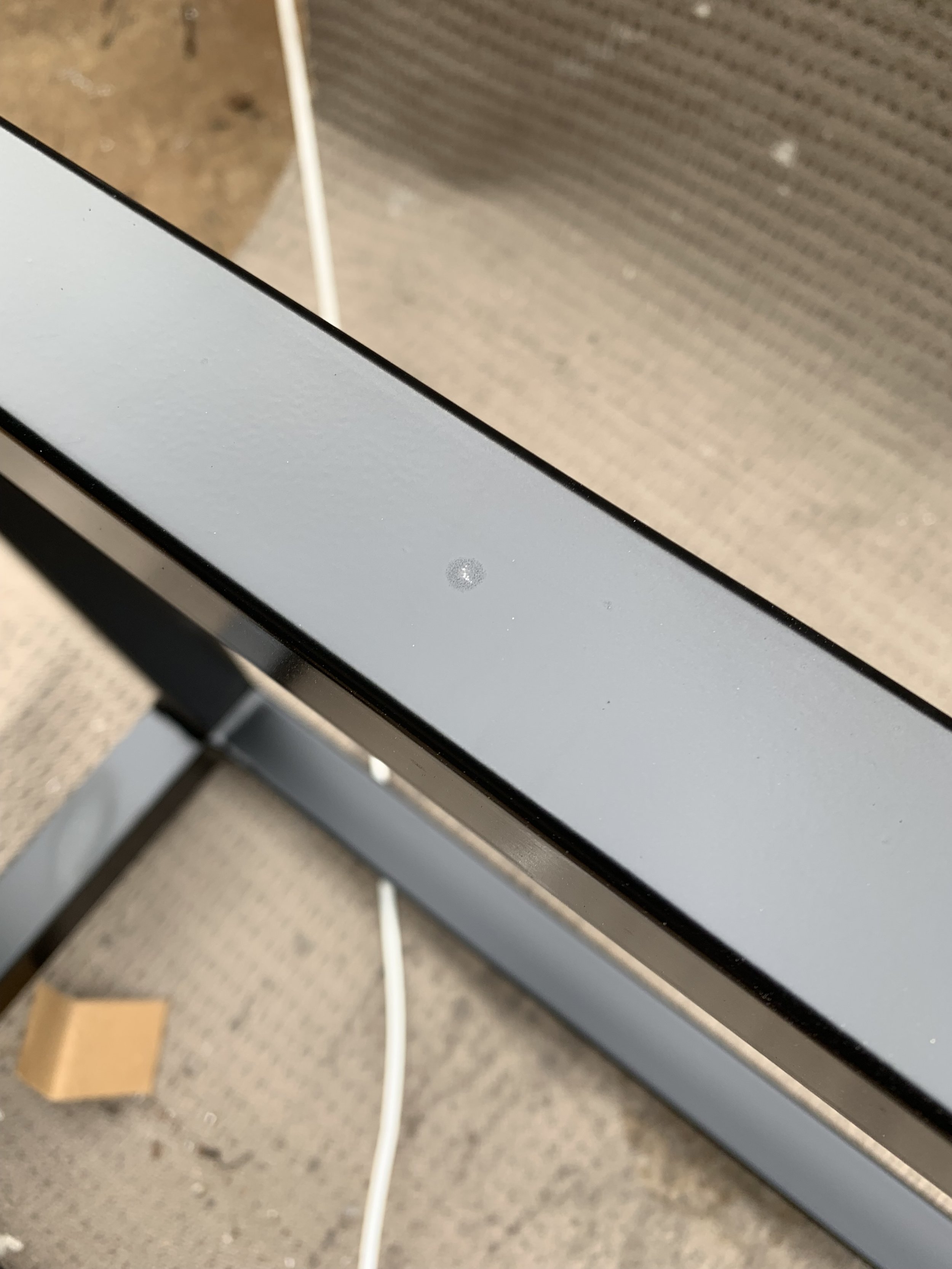

Subsequently eliminating this wax contamination relies on manual identification and removal. Given the difficulty in visually identifying the wax residue and the potential for small clumps to be present almost anywhere on the product, it is almost impossible to fully remove this contaminant from every surface, every time. Lubricating wax contamination is a leading cause of defects in powder coated finishes from our process.

Instead of risking these contamination issues, we recommend our customers eliminate the use of these waxes in their manufacturing processes when they regularly send products for powder coating or painting. For cutting blades and milling processes we recommend the use of cutting lubricant Lunasol Ultra.

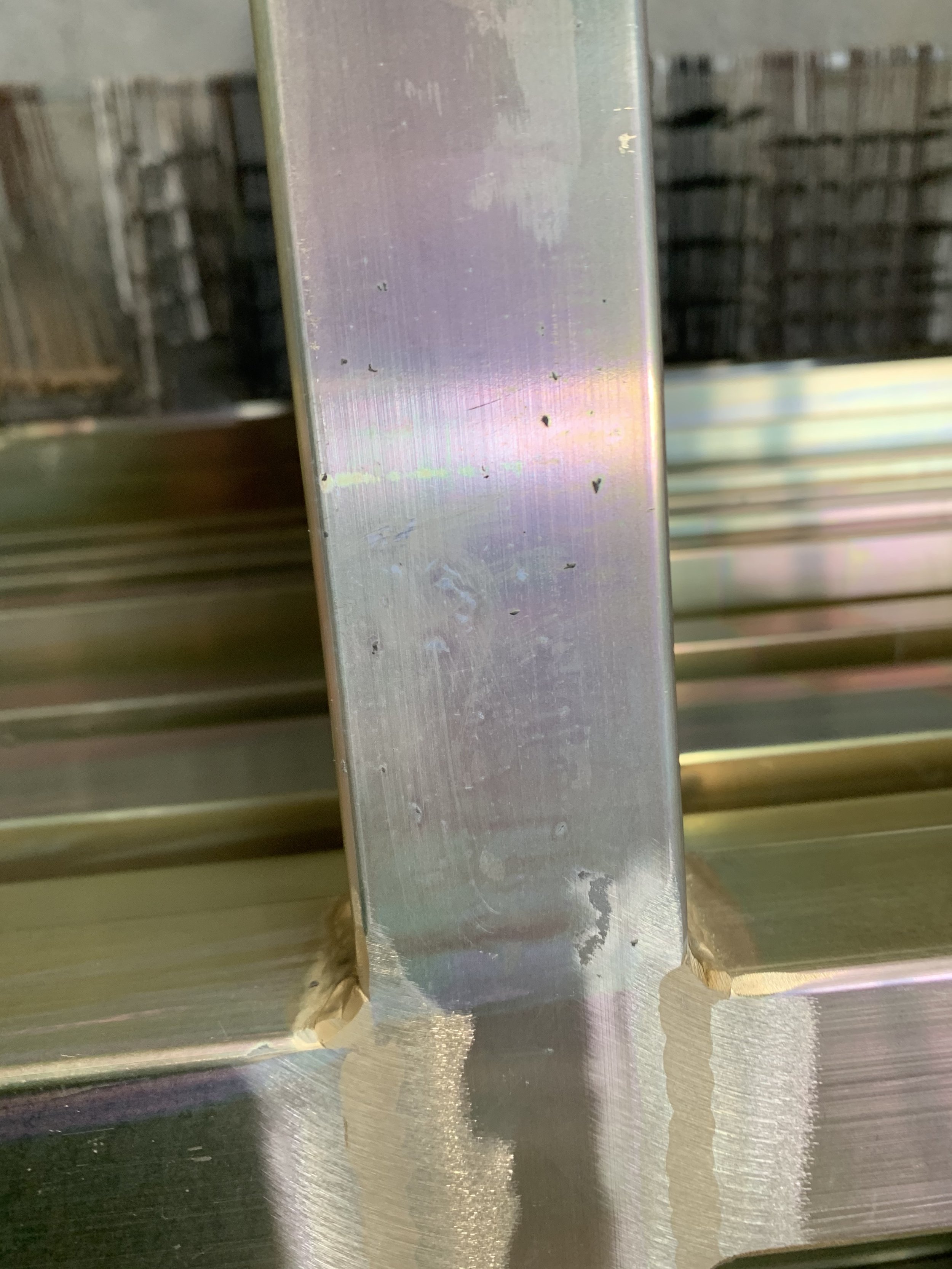

However for grinding applications we have found 3M Scotch-Brite Surface Conditioning Discs (SC-DH) to be a productive option that eliminates the need for lubricating wax in the manufacturing process.

These discs with Aluminium Oxide (Grade A) abrasive, are available in various grades of abrasiveness and offer excellent grinding and finishing capabilities whilst eliminating the risk of lubricating wax contamination for non-ferrous substrates such as aluminium.

Coarse (A CRS - Brown): Ideal for heavy grinding of aluminium substrates.

Medium (A MED - Maroon): Perfect for light grinding, deburring, and finishing of aluminium substrates (best all-rounder).

Very Fine (A VFN - Blue): Best for fine deburring and finishing of aluminium substrates.

You can find these discs at industrial product suppliers such as Blackwoods and Sydney Tools amongst many others. Simply search for the 3M Ordering code in the table above for the size / grade applicable to suit your workshop needs.

Switching to these products will enable the elimination of lubricating wax usage in your manufacturing process, thus supporting us to deliver defect free, high-quality powder coated finishes every time.